The Flying Car Mechanic Network

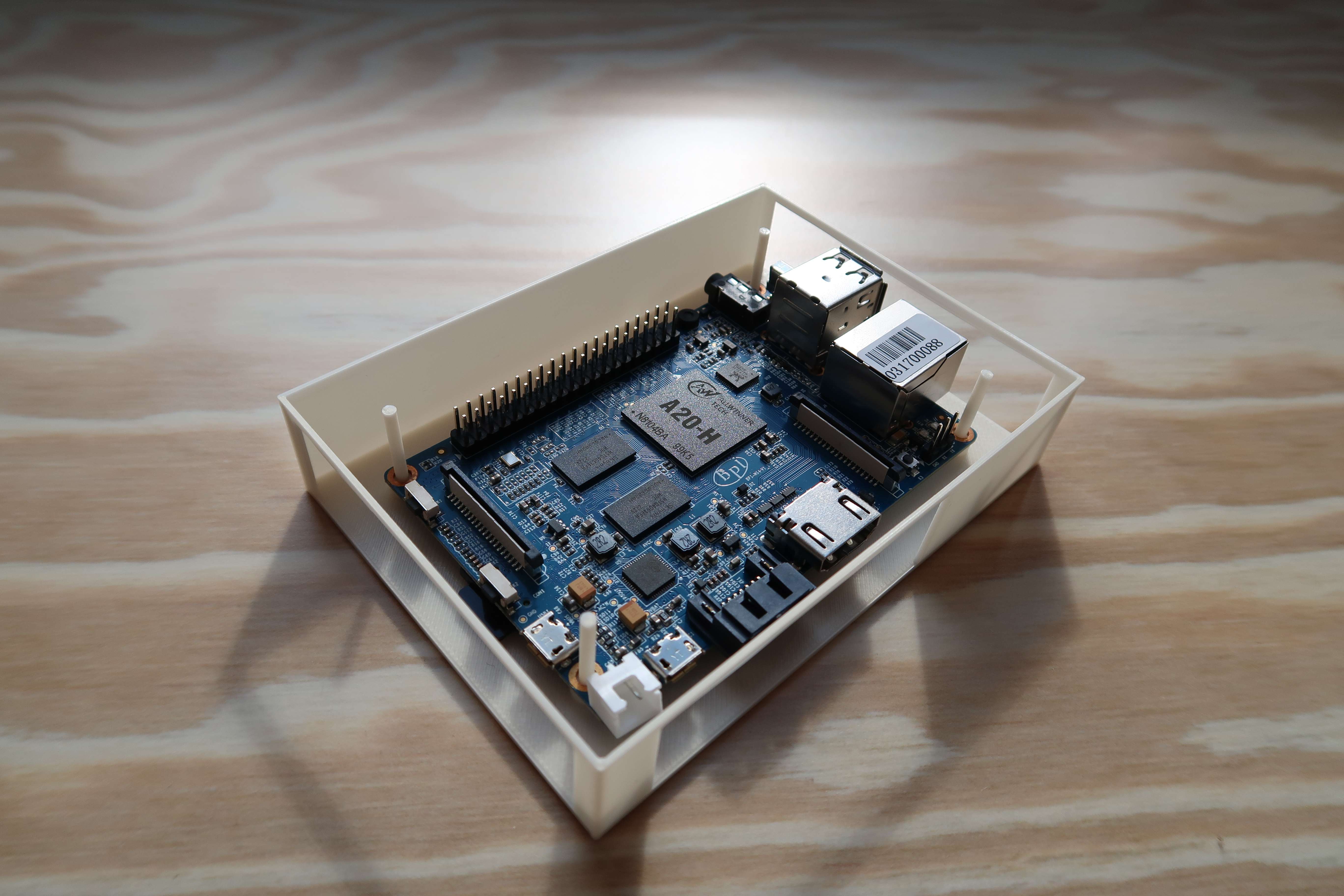

How did we get here? I started this project because I wanted to design, manufacture, and sell a personal computer that safeguards its user’s attention. This means that I had to make both the hardware and the software to control the user experience from end to end. Very quickly I learned that manufacturing and distributing the hardware is much harder than I expected. Following that disappointing discovery, I resigned to working on just the Operating System while relying on someone else to manufacture the computer. The single-board computer (SBC) I chose to use as the platform did not have a case. In fact, it was a raw circuit board which makes it rather unappealing to anyone bar the most daring early adopters. So, I set off to make a case for it that I could 3D print and market. It was during this step of the journey that a light bulb went off in my head which brings us to this post.

Over the past week, I have been working on a case for the Flying Car that I could manufacture and sell.

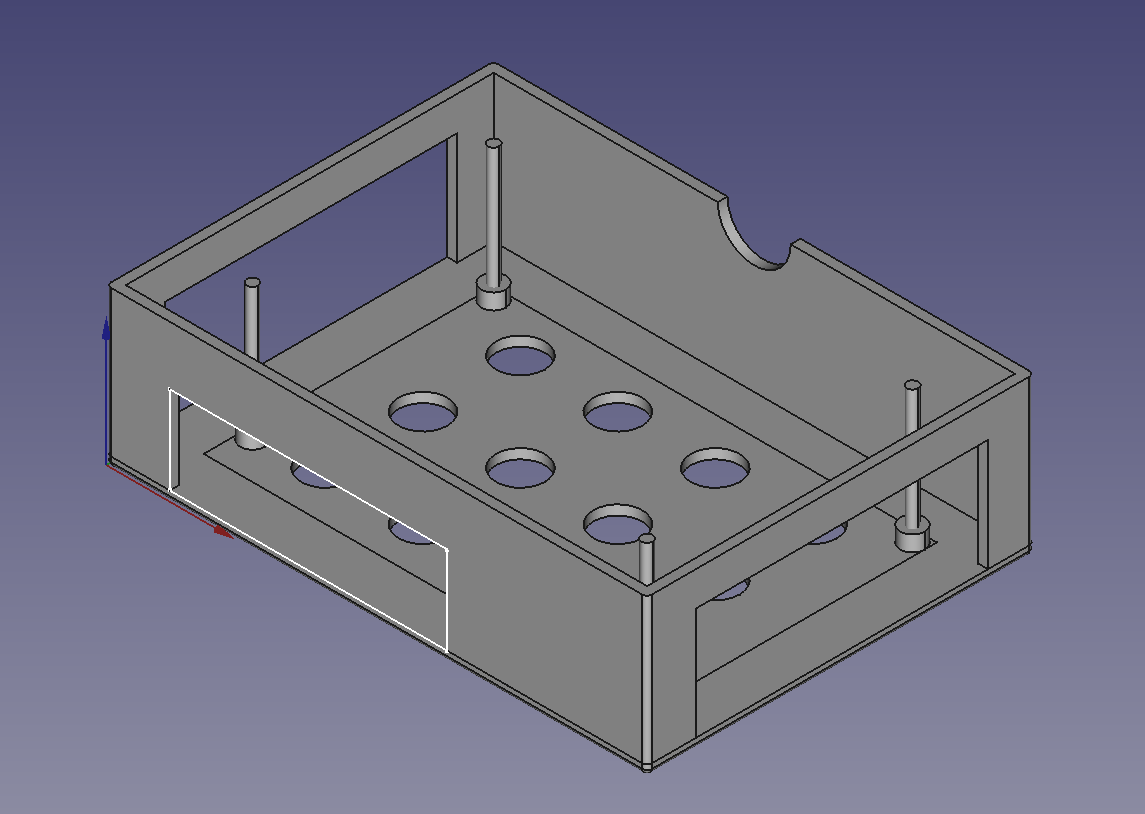

A long time ago, I made some 3D models using 3D Studio Max, but 3D printing was still a completely new challenge for me.

This time, I had to learn how to design a physical object in FreeCAD, an open-source community project that competes against costly proprietary alternatives.

Once the design was complete, I had to export the model and preview the printing process in something called the Prusa Slicer. It was illuminating to see how the different shapes and details would be printed when the time comes to bring the object into the physical world.

That’s when I made my first naive mistake: I had assumed that measurements for the PCB which I found online were accurate, and the case would have no alignment issues. It turns out that I was dead wrong. Luckily, I caught this early and remeasured everything on the actual device using a ruler, pencils, and paper. It felt refreshingly old-school.

Next, came the choice of 3D printing material. I planned to use PCBWay to manufacture the cases. Their website provides guidance on choosing the material and how each choice affects the recommended wall thickness. PCBWay quoted me US$7 to make the case out of something called PETG, a safe non-toxic material used in food containers. The build time would have been about one week, and it would take a while for it to ship to me. Confident as I was with my ruler skills, I felt it prudent to print a prototype and test it with the PCB before sending the model to the manufacturer.

Fortunately, a friend had a 3D printer and offered to print one for me. It came out perfectly on the first try! This gave me an idea.

The big idea

Instead of me having the deal with import, export, inventory, shipping, and customs, why can’t my customers have the case (or other modules for that matter) manufactured by someone in their community? All I would have to do is open-source and publish the designs.

And why stop at 3D printing cases? Why not make it possible to get help (with soldering, sourcing components, assembling modules, etc.) for your Flying Car from someone in your city?

What does all of this mean for an owner of a Flying Car?

It means that as long as the modules match the spec, you could use your community to assemble and endlessly repair, modify, upgrade, and extend your Flying Car. The Flying Car OS is at the heart of this and ensures that all modules can talk to each other, regardless of how and where they were assembled.

And so the Flying Car Mechanic Network was born.

The Flying Car garage

As the first mechanic, my “garage” is Geneva, Switzerland. If you or someone you know wishes to help members of their community in this way, then fill out this form and list your equipment and capabilities.

Looking at the future, I can open-source all the design and manufacturing files that someone would need to be able to order the PCB for the Flying Car “Compute Module” from PCBWay or another PCB manufacturer. In fact, PCBWay just quoted me US$10,200 to design an SBC around the A20 SoC and agreed to use KiCad, an open-source community project that focuses on electrical design. This would liberate the Flying Car community from a single SBC designer and manufacturer. It would also solve the biggest challenge that I currently face in distributing the hardware that can run Flying Car OS.

When you are just one person or one entity, the full brunt of responsibility (and liability) falls on your shoulders. But what if you were not alone? What if you were one of many? If you could “deploy” your designs to millions of Flying Car garages just by clicking a button? Let’s call this “Hardware as code.”

Who knows, maybe one day we could even pay SiFive the US$100,000 fee to design and open-source a RISC-V chip. Then Flying Car mechanics could order this chip directly from a fab, which would remove the dependence on Allwinner, the manufacturer of the SoC. If none of the above makes sense to you, this discussion might help.

The skies are clear. See you up there.

Follow along on my adventure by subscribing to the mailing list!